Date

Date and Time

October 21, 2020 03:45 PM (PDT)–04:45 PM (PDT)

Abstract

Cementing operations still continue to be the most sensitive and important stages in the drilling and completion operations of oil, gas and geothermal wells. An inadequate cement slurry design and the stresses a cement sheath encounters most especially when exploiting High-Temperature and High-Pressure wells can lead to loss of zonal isolation and other related downhole problems, jeopardizing the future of the well. A good blend of cement and cementing job practices can stipulate good quality cementing and cement sheath integrity resilient to withstand several temperatures and pressure cycles over the life of the well; consequently very beneficial to the drilling and completion and production operations cost effectiveness and success.

The motivation of this study lays on the need to evaluate the remaining useful neat cement strength in an elevated temperature condition as a function of time. An experimental study has been conducted by performing a destructive and non-destructive test on multiple neat cement samples in the laboratory. Furthermore, the paper investigates and develops correlations using the experimental dataset that will aid in predicting the strength of neat cement when subjected to different failure modes by leveraging data analysis method in the Python environment. The findings indicated that the cement mechanical properties show a better error distribution at a higher temperature compared with room conditions. Low temperature curing conditions show a wider spread of the unconfined compressive strength values, and thus, this will imply that shallower wells, may be difficult to be evaluated using a reduce number of samples. This may imply that use of statistical approaches to estimate well integrity may differ as a function of curing temperature.

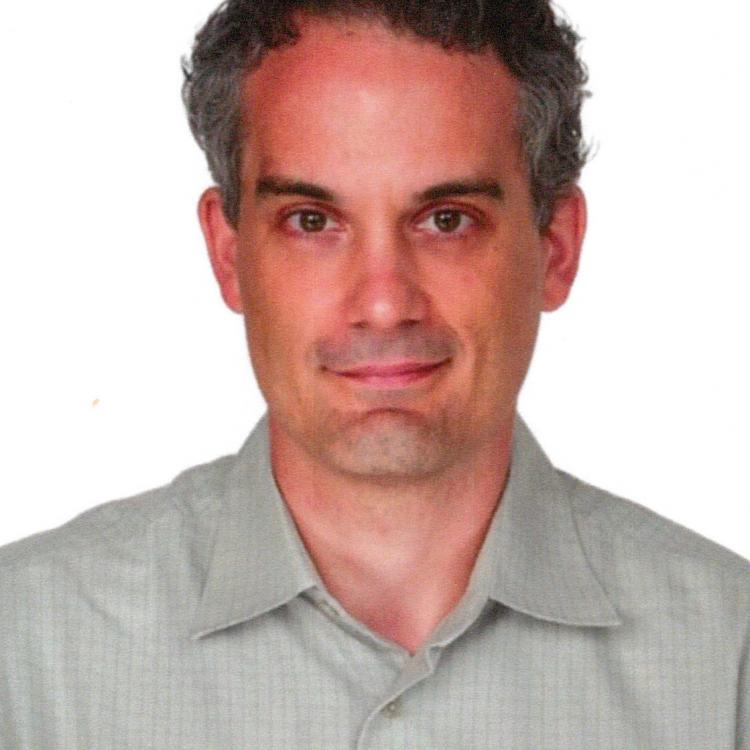

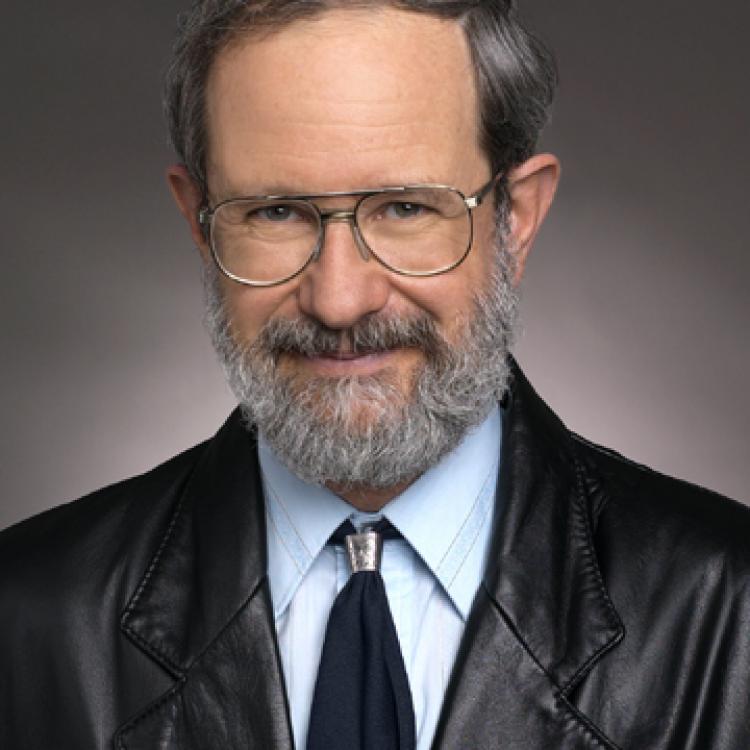

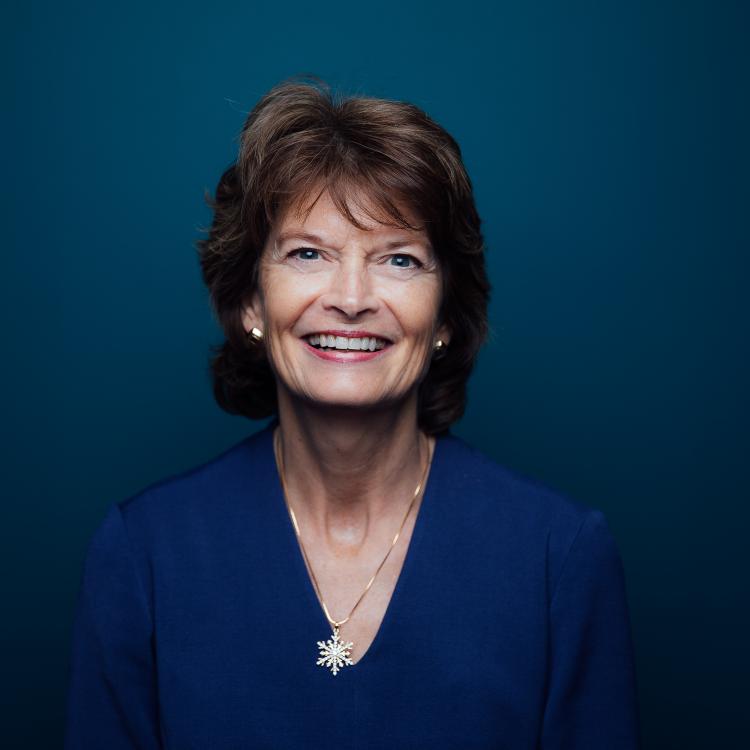

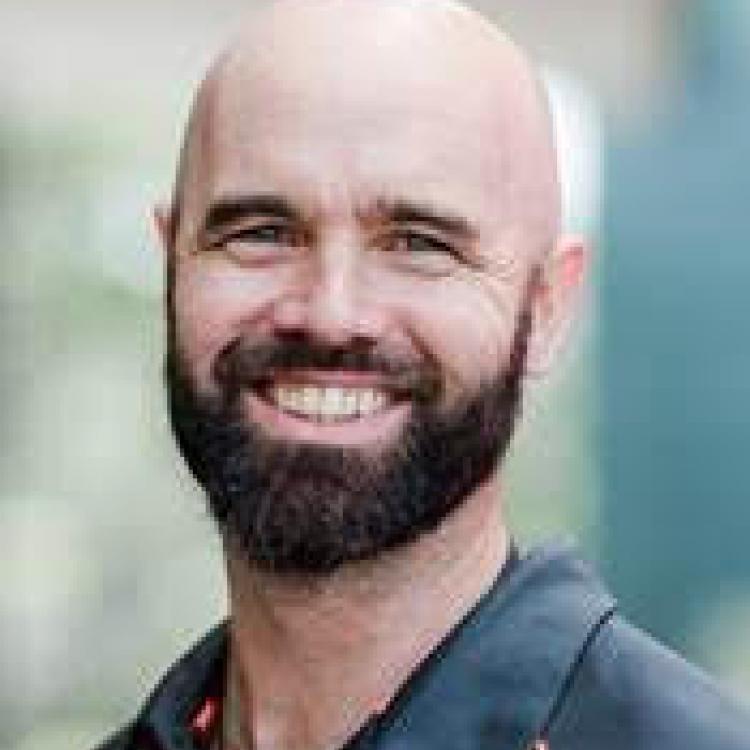

Speakers

Session Code

TSWA12