Steam turbines in geothermal flash or direct steam plants are subject to moisture erosion due to exhaust end moisture and corrosion due to the chemistry of the steam found in typical geothermal resources. As steam turbine blade design technology improves, the turbine efficiency increases which results in even greater amounts of moisture on tall blades in the exhaust. Without properly designed moisture removal features in the steam path and blades provided with erosion resistant materials, high moisture will increase the amount of erosion in the rotating blades. Without proper maintenance, the reliability and performance will degrade over time. Another well known fact is that removing blades on steam turbines that have operated in geothermal service for an extended amount of time is extremely difficult. The corrosive steam virtually welds the blades to the wheels. In many cases axial entry blade roots are required for the tall blades in the exhaust section of the turbine. This configuration results in even more severe erosion, making blade removal very difficult without damaging the rotor. This paper reports on some of the past practices of protecting tall blades in geothermal service and introduces an in-situ solution that can significantly increase the life of the blading and save cost. The objective of this paper is to present this incremental technology to give plant operations managers the knowledge of how to extend the life of their exhaust end blading and to understand the risks if the blades are not properly removed.

Date

Date and Time

October 22, 2020 11:30 AM (PDT)–12:30 PM (PDT)

Sponsors

Abstract

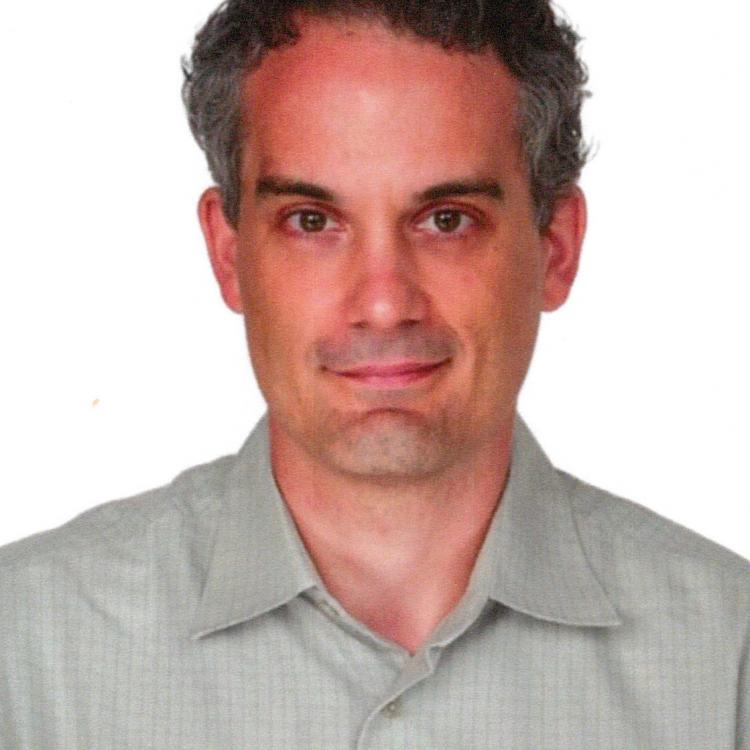

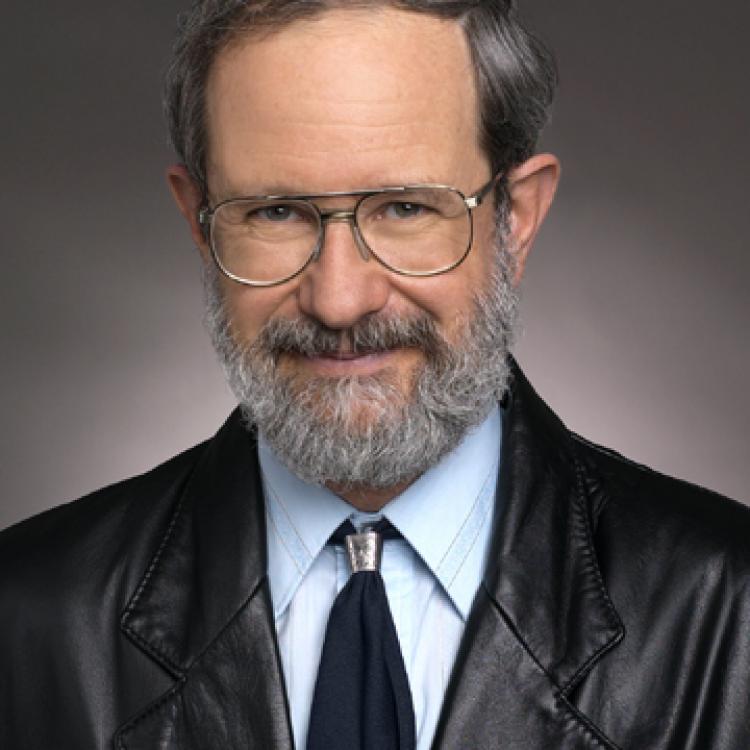

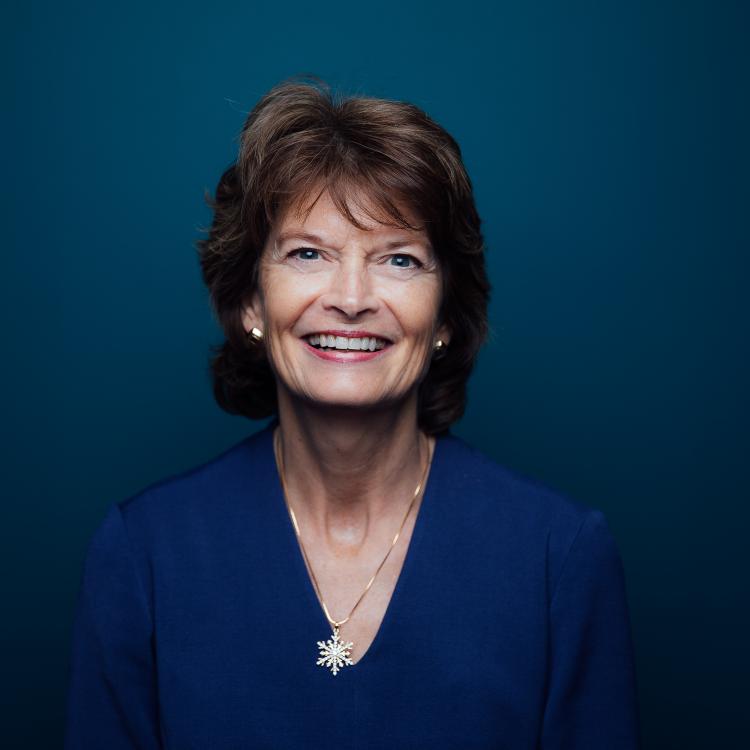

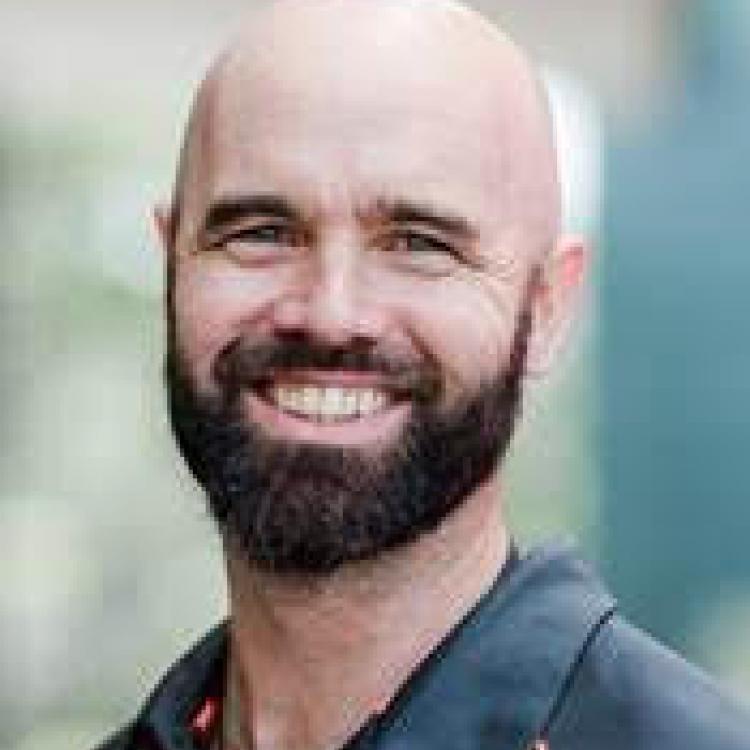

Speakers

Session Code

TSTHB6